The GBS Zero stands out for a number of compelling reasons, making it an ideal choice for anyone seeking a thrilling, personalized sports car experience:

The Zero is available in both self-build and factory-build options, giving you the flexibility to choose the experience that best suits your needs and desires. If you're a hands-on enthusiast looking for the satisfaction of building your own sports car, the self-build option provides you with everything you need to assemble your very own Zero, with the support and guidance of our team. For those who prefer a ready-to-drive experience, the factory-build option allows us to take care of the entire build process for you. Our skilled technicians will build your Zero to the highest standards, ensuring it’s fully prepared for the road.

Whichever route you choose, you’ll end up with a beautifully crafted, high-performance sports car designed for pure driving pleasure! Contact us today to explore the options and make your dream a reality

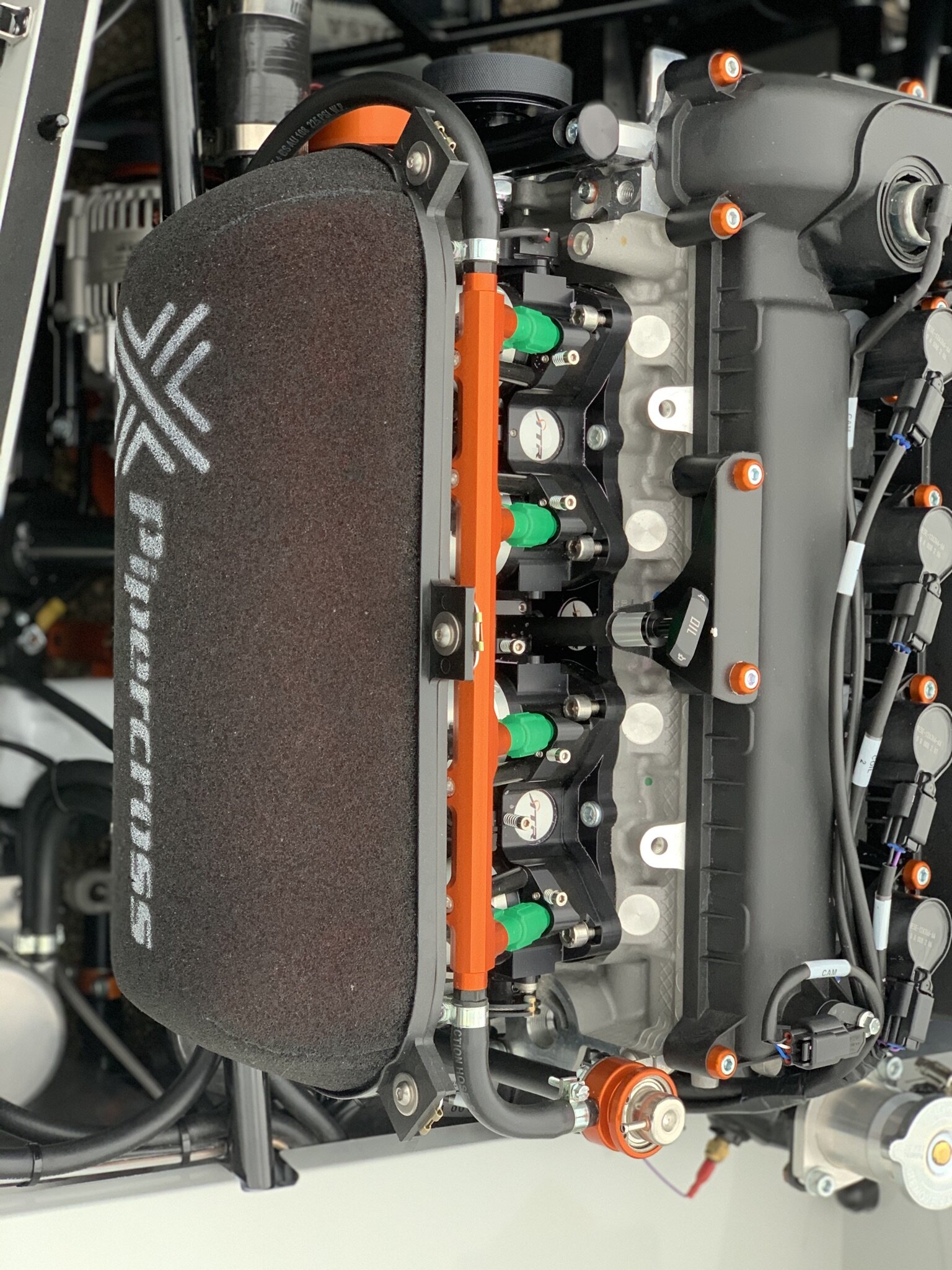

1. Exceptional Performance: Designed with lightweight engineering, the GBS Zero delivers agile handling and impressive acceleration, making it perfect for both track days and spirited road driving. Its precision-tuned suspension and customisable engine options ensure that drivers experience responsive control and dynamic performance.

2. Customisation: Whether you choose to build it yourself or opt for a fully assembled version, the Zero offers a wide range of customisation options. From engine choices to brake setups and interior details, each car can be tailored to suit individual preferences, ensuring a unique driving experience.

3. DIY Enthusiast Appeal: For those who love the hands-on approach, the GBS Zero kit provides an opportunity to build a car from the ground up. GBS offers comprehensive support, parts, and guidance throughout the process, making it a rewarding project for enthusiasts.

4. Track-Ready Capabilities: The Zero’s lightweight frame and nimble performance make it a perfect fit for the track. Whether you’re a seasoned racer or a weekend enthusiast, the GBS Zero delivers the thrill and precision needed to perform in competitive environments.

5. British Craftsmanship: Hand-built in the UK, the Zero reflects the rich heritage of British sports car manufacturing. Its classic styling, combined with modern engineering, ensures a timeless aesthetic alongside cutting-edge performance.

6. Affordability and Value: Compared to other performance cars, the GBS Zero offers exceptional value. It provides the excitement and quality of high-end sports cars at a fraction of the cost, especially with the option to build it yourself.

7. Community and Support: GBS is not just a car manufacturer, it’s a community. Owners benefit from excellent customer support, access to events like track days, drive outs, Cars & Coffee and a passionate network of fellow enthusiasts.

For anyone seeking a unique blend of craftsmanship, performance, and the excitement of a true driving experience, the GBS Zero delivers on every level. It’s more than just a car—it’s an adventure in motoring. Contact us today to discuss your Zero specification and options.