The learning curve of building a Zero is one the most rewarding things I have ever done......

/We always love to see photographs and hear about customers Zero build stories and experiences they have had and how we as a team can improve and make the build experience even better and more enjoyable. GBS customer Andrew Ives has been enjoying his Zero on the road for some time and we asked him to write a few words about his experience…….

My name is Andrew and I've been asked to write something about my experience with the highs and lows of building and owning my own GBS zero race.

After lots of research and meeting the team at a car show, followed by a factory visit, I made the decision to go with GBS for lots of reasons but mainly for their attention to detail, and design. The quality of the wielding and powder coating on the frames and parts was also a very good reason as its nothing short of remarkable.

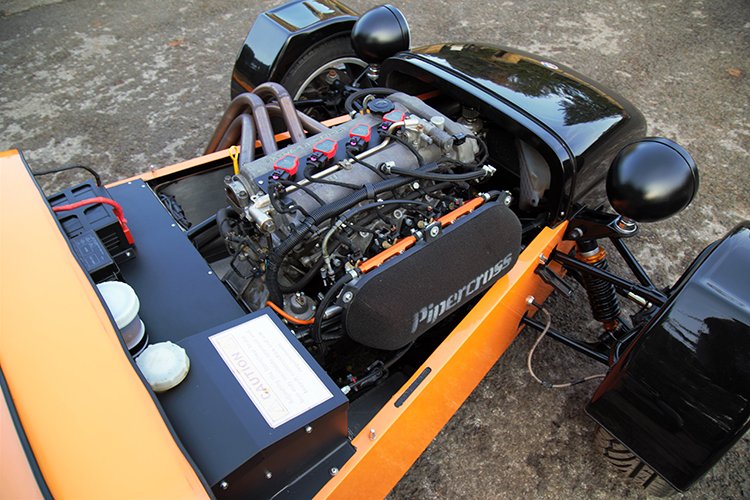

With the build, I took my time. From the trestles to being on the road, it took me just under 4 years. I would say the whole build went as I envisioned it, with only a couple of surprises, one having to do the IVA 3 times down to just emissions, funnily the road tax on my Zero is less than the MX5 the engine came from! And two, having to shell out an extra £900+ on individual throttle bodies because the MX5 engine plenum would not fit in the engine bay, at first this stung but now in hindsight it may be the best upgrade on the car and I would highly recommend them. Talking of upgrades, well one that I chose to buy, I would also recommend the solid rear end bushes as they transform the feel of the rear end and you can set up the geometry exactly how you like it.

Being 6 foot 4 and fed up of feeling cramped in other 7en's, I chose the GT frame. The GT also only comes with lowered floors which meant I had lots of headroom for my crash hat under the roll cage, this means I wouldn't have a problem with scrutineering on race events. I've owned and done a lot of work on MX5's, so it was an easy choice to go down the MX5 donor root. It also kept the cost down, then and now due to parts being cheap.

At first, I thought I may have bitten off more than I can chew, as I decided to build as much of the car as I possibly could, starting with the ECU, a Megasquitrt MS3X kit. A full engine and diff rebuild. A custom wiring loom to my own design but using the fuse box from the MX5. The headlight switch I used from a VW Golf, this helped with the IVA fog light rule. Setting up the geometry, doing the tuning and finally taking it through the IVA. But this was another nice thing about GBS and kit spares, If I got stuck at any point, I was safe in the knowledge that I could just call GBS for help or spend some money for a short cut to get me over the finish line.

And yes, without question, before I started, the idea of not having a build manual was terrifying but looking back on it now, it allowed me the freedom to build something fit for my purpose and unique to my needs.

I'm currently using the car on the road and track but also for grassroots motorsport which has to be the most enjoyable thing I do with the car. Being a member of Farnham district motor club has opened up a world of new possibilities that I've only just started to discover. Click here to watch a short video.

If you're like me and grew up building RC cars and unable to stop yourself thinking about everything on wheels, you have to put building a kit car on you bucket list. The learning curve of building a Zero is one of the most rewarding things I have ever done! - A. Ives